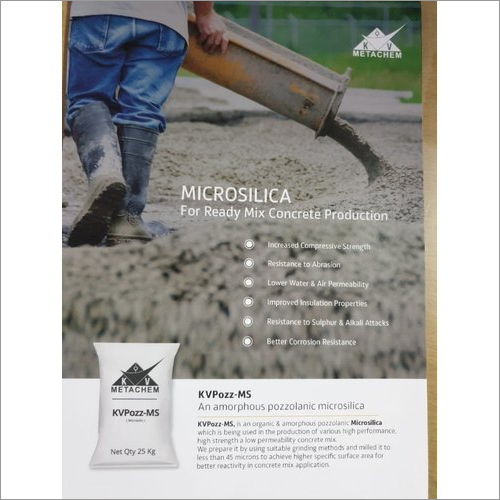

Micro Silica (Replacement Of Cement)

Price 14 INR/ Bag

Micro Silica (Replacement Of Cement) Specification

- Application

- Replacement of cement in concrete to improve strength and durability

- Shape

- Powder

- Porosity

- Low

- Dimensional Stability

- High stability under thermal and mechanical stress

- Strength

- Enhances compressive and tensile strength of concrete

- Specific Gravity

- Approx. 2.2

- Thermal Conductivity

- Low thermal conductivity improves resistance to thermal shocks Calorie (IT)/second/centimeter/C

- Chemical Composition

- Silica (SiO2) > 85%

- Color

- Light grey

Micro Silica (Replacement Of Cement) Trade Information

- Minimum Order Quantity

- 100 Bags

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About Micro Silica (Replacement Of Cement)

Superior Durability and Strength Enhancement

Micro Silica provides notable improvements to the mechanical properties of concrete, substantially boosting both compressive and tensile strength. Its refined structure and low porosity make it an excellent choice for environments where durability, longevity, and resistance to thermal fluctuations are critical.

Adaptable Applications in Indian Construction

Widely utilized across India by manufacturers, exporters, suppliers, and traders, Micro Silica is integrated into concrete mixes as a partial replacement for cement. This not only optimizes construction material efficiency but also enhances overall performance for infrastructure projects.

FAQs of Micro Silica (Replacement Of Cement):

Q: How does Micro Silica improve the strength of concrete when used as a partial replacement for cement?

A: Micro Silica enhances both the compressive and tensile strength of concrete due to its fine particle size, low porosity, and high silica content. When added to a concrete mix, it fills the gaps between cement particles and contributes to a denser, more robust matrix.Q: What are the key benefits of using Micro Silica in construction applications?

A: The primary benefits include significant improvements in concretes strength and durability, high dimensional stability under thermal and mechanical stress, and increased resistance to thermal shocks. Its low porosity also reduces water penetration, improving the overall longevity of structures.Q: When is it most suitable to use Micro Silica as a replacement for cement in concrete projects?

A: Micro Silica is most advantageous in projects requiring high-performance concrete, such as bridges, tunnels, high-rise buildings, and industrial floors, or any situation where enhanced durability and strength are essential.Q: Where can Micro Silica be sourced in India?

A: This product is available across India through various channels, including distributors, exporters, manufacturers, suppliers, and traders who specialize in advanced construction materials.Q: What is the process for incorporating Micro Silica into a concrete mix?

A: Micro Silica is typically added as a powder form during the mixing stage, replacing a portion of cement (commonly 5% to 10% by weight). Proper mixing ensures uniform dispersion, crucial for achieving optimal performance characteristics in the final concrete.Q: How does the low thermal conductivity of Micro Silica benefit construction materials?

A: Low thermal conductivity provides enhanced resistance to thermal shocks and sudden temperature changes, helping concrete structures maintain their integrity in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Microsilica Category

Micro silica

Price 360 INR / Kilograms

Minimum Order Quantity : 10 Tonnes

Color : Gray to offwhite

Strength : Improves compressive strength of concrete

Chemical Composition : SiO2 ~ 9096%, Minor elements

Application : Used as a pozzolanic material in concrete, construction, and refractory applications

Black Micro Silica

Price 10 INR / Kilograms

Minimum Order Quantity : 1 Ton

Color : Black

Strength : High compressive strength

Chemical Composition : SiO2 > 85%, rest other oxides

Application : Construction, Concrete Admixtures, Refractory

Fume Micro Silica

Price 10 INR / Kilograms

Minimum Order Quantity : 1 Ton

Color : Grey to dark grey

Strength : Enhances compressive and flexural strength of concrete

Chemical Composition : SiO2 > 90%, Al2O3 < 1.5%, Fe2O3 < 0.5%, CaO < 1.0%

Application : Concrete, refractories, cement, and construction

Pozzolanic Micro Silica

Price 2100 INR / Kilograms

Minimum Order Quantity : 10 Tons

Color : Gray.

Strength : Improves compressive strength of concrete.

Chemical Composition : Silicon dioxide (SiO2).

Application : Used in highperformance concrete production.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free