Micro Silica Powder

Price 10 INR/ Kilograms

Micro Silica Powder Specification

- Surface Finish

- Fine Powder

- Hardness (%)

- N/A (Amorphous Powder)

- Water Absorption

- Negligible

- Melting Point

- >1600C

- Usage & Applications

- High performance concrete, shotcrete, precast, oil well grouting, refractories

- Purity(%)

- >85%

- Form

- Fine Powder

- Chemical Composition

- SiO2 > 85%, with minor Al2O3, Fe2O3, CaO

- Density

- 700 Gram per cubic centimeter(g/cm3)

- Application

- Construction, Refractory, Concrete, Cement, Oil Well Grouting

- Product Type

- Pozzolanic Micro Silica Powder

- Types of Refractories

- Silica Based Refractory Material

- Shape

- Amorphous Powder

- Porosity

- Very Low

- Dimensional Stability

- Excellent at High Temperatures

- Strength

- Improves compressive, flexural & bond strength

- Specific Gravity

- 2.2 2.3

- Thermal Conductivity

- Low

- Color

- Grey to Light Grey

- ISO Certification

- ISO 9001:2015 certified processing

- Moisture Content

- <1.5%

- Particle Size

- D50 < 1 micron

- pH Value

- 6.0 - 7.0 (at 20°C in water suspension)

- Loss on Ignition

- <4.0%

- Packing

- 25 kg bags / Jumbo bags

- Grain Shape

- Spherical, amorphous

Micro Silica Powder Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 10 Tons Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Micro Silica Powder

Here, we provide you with wide range of Micro Silica Powder which provides a more uniform distribution and a greater volume of hydration products. This powder reduces thermal cracking, improves durability, and increases strength. It is produced by some chemical processing of the ash. This powder decreases the average size of pores in the cement paste. This powder n concrete improves its strength and durability. Micro Silica Powder is an excellent admixture for concrete as it leads to better engineering properties. This powder concrete has a number of construction applications. This powder is very cost effective and can be easily purchased by our clients at cheaper rates, as per their requirements.Superior Performance in Construction and Refractories

Micro Silica Powder is engineered to enhance the quality and durability of concrete, cement, and refractory products. Its ultra-fine particle size and high silica content improve compressive strength and reduce permeability, offering long-lasting structural benefits for large-scale projects.

Certified Quality Assurance and Versatile Packaging

Processed under ISO 9001:2015 standards, Micro Silica Powder meets rigorous quality benchmarks. Available in user-friendly 25 kg bags and bulk jumbo bags, it supports flexible supply requirements for distributors, exporters, and manufacturers across diverse sectors in India.

FAQs of Micro Silica Powder:

Q: What are the primary applications of Micro Silica Powder?

A: Micro Silica Powder is widely used in high-performance concrete, shotcrete, precast elements, oil well grouting, and silica-based refractory materials, due to its ability to improve strength and durability.Q: How does Micro Silica Powder benefit concrete and cement formulations?

A: Micro Silica Powder enhances compressive, flexural, and bond strength, lowers water permeability, and significantly contributes to the durability of concrete and cement. Its fine, spherical particles provide a denser matrix and improved chemical stability.Q: When should Micro Silica Powder be added during the mixing process?

A: For best results, Micro Silica Powder is incorporated during the initial stages of mixing with other raw materials to ensure even dispersion and optimal performance in the final product.Q: Where is Micro Silica Powder typically sourced and supplied?

A: This product is available through manufacturers, distributors, suppliers, and traders in India, and can be packaged in both 25 kg bags and jumbo bulk bags depending on project scope and logistics requirements.Q: What is the process behind manufacturing Micro Silica Powder?

A: Micro Silica Powder is produced as a byproduct of silicon and ferrosilicon alloy manufacturing. The amorphous, spherical silica particles are extracted, purified, and tested to maintain high purity standards, as specified by ISO certifications.Q: Is Micro Silica Powder safe to use in oil well grouting and high-temperature refractories?

A: Yes. Its high SiO2 content, low porosity, and melting point above 1600C ensure excellent dimensional stability and integrity in both oil well grouting and refractory applications, even at elevated temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Microsilica Category

Fume Micro Silica

Price 10 INR / Kilograms

Minimum Order Quantity : 1 Ton

Strength : Enhances compressive and flexural strength of concrete

Thermal Conductivity : Low

Shape : Other, Amorphous, spherical particles

Specific Gravity : 2.2

Pozzolanic Micro Silica

Price 2100 INR / Kilograms

Minimum Order Quantity : 10 Tons

Strength : Improves compressive strength of concrete.

Thermal Conductivity : Low thermal conductivity. Calorie (IT)/second/centimeter/C

Shape : Other, Fine powder.

Specific Gravity : 2.2.

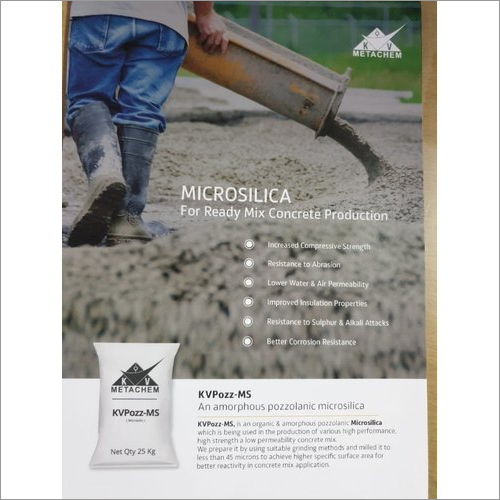

Micro Silica For RMC

Price 21 INR / Kilograms

Minimum Order Quantity : 10 Tons

Strength : Enhances concrete strength

Thermal Conductivity : Low Calorie (IT)/second/centimeter/C

Shape : Powder

Specific Gravity : 2.2

Micro Silica

Price 15 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Strength : Enhances strength of refractory materials

Thermal Conductivity : Low

Shape : Powder, Powder

Specific Gravity : 2.2 2.3

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free