Black Micro Silica

Price 10 INR/ Kilograms

Black Micro Silica Specification

- Surface Finish

- Smooth

- Usage & Applications

- Used in high-strength concrete, shotcrete, oil well grouts, refractory and ceramic products

- Hardness (%)

- 60-70%

- Application

- Construction, Concrete Admixtures, Refractory

- Purity(%)

- >85%

- Density

- 700 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- SiO2 > 85%, rest other oxides

- Form

- Powder

- Water Absorption

- Low

- Melting Point

- 1600C - 1700C

- Product Type

- Micro Silica powder

- Types of Refractories

- Silica-based refractory

- Shape

- Spherical powder

- Porosity

- Very low

- Dimensional Stability

- Excellent

- Strength

- High compressive strength

- Specific Gravity

- 2.2 - 2.3

- Thermal Conductivity

- Low

- Color

- Black

Black Micro Silica Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 10 Tons Per Day

- Delivery Time

- 1 Week

About Black Micro Silica

Expansive Applications of Black Micro Silica

Beyond concrete admixtures, Black Micro Silica is extensively deployed in infrastructure, refractory linings, and plant-based ceramics. Its versatility spans oil well grouts, shotcrete, and high-strength industrial flooring, making it indispensable across varied domains. Plants and manufacturers utilize it to enhance thermal stability and dimensional consistency, while its integration in silica-based refractories delivers grandiose resistance against extreme heat and chemicals in industrial environments.

Sample Availability and Packaging Specifics

Black Micro Silica samples are provided for quality evaluation, subject to proposal amount and order completion terms. Samples come in securely packed HDPE bags to preserve product integrity. Our sample policy accommodates asking price inquiries, and packaging options include jumbo bags for bulk requirements. Once an order is confirmed, suppliers ensure prompt dispatch and adherence to storage conditions, making procurement seamless for local and export clients alike.

FAQs of Black Micro Silica:

Q: How is Black Micro Silica utilized in the construction industry?

A: Black Micro Silica is mainly mixed into concrete to enhance compressive strength, durability, and reduce permeability. Its high pozzolanic reactivity makes it a vital admixture for producing advanced, long-lasting structures.Q: What are the main benefits of using Black Micro Silica in refractory applications?

A: The low porosity and phenomenal thermal stability of Black Micro Silica make it ideal for silica-based refractories. It ensures excellent dimensional stability and resistance against high temperatures and chemical corrosion.Q: Where can Black Micro Silica be stored to maximize shelf life?

A: Black Micro Silica should be stored in a cool, dry place within HDPE or jumbo bags to maintain its effectiveness and achieve its 12-month shelf life.Q: When is a sample of Black Micro Silica typically provided to clients?

A: Samples are usually offered during the proposal or procurement stage, allowing clients to assess quality before full-scale order completion.Q: What is the process for ordering Black Micro Silica from India-based suppliers?

A: Buyers can request a quote, negotiate the asking price, and finalize their proposal amount. Upon order completion, product is packed securely and dispatched as per the agreed specifications.Q: How does Black Micro Silica improve the surface finish and strength of concrete?

A: Due to its spherical powder form and high SiO2 content, Black Micro Silica fills pores, reduces water absorption, and imparts a smooth finish with high compressive strength to concrete structures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Microsilica Category

Micro silica

Price 360 INR / Kilograms

Minimum Order Quantity : 10 Tonnes

Strength : Improves compressive strength of concrete

Chemical Composition : SiO2 ~ 9096%, Minor elements

Dimensional Stability : Other, High dimensional stability

Application : Used as a pozzolanic material in concrete, construction, and refractory applications

Fume Micro Silica

Price 10 INR / Kilograms

Minimum Order Quantity : 1 Ton

Strength : Enhances compressive and flexural strength of concrete

Chemical Composition : SiO2 > 90%, Al2O3 < 1.5%, Fe2O3 < 0.5%, CaO < 1.0%

Dimensional Stability : Other, Excellent dimensional stability at high temperature

Application : Concrete, refractories, cement, and construction

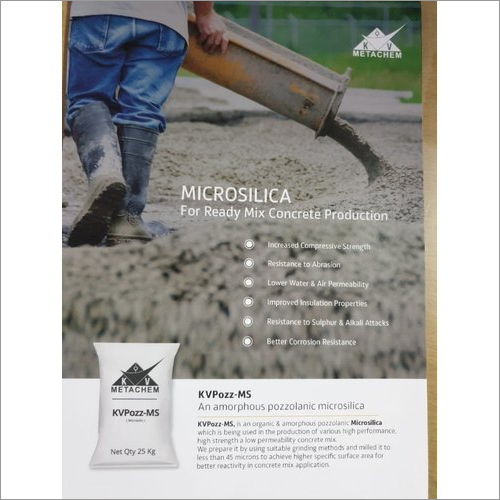

Pozzolanic Micro Silica

Price 2100 INR / Kilograms

Minimum Order Quantity : 10 Tons

Strength : Improves compressive strength of concrete.

Chemical Composition : Silicon dioxide (SiO2).

Dimensional Stability : Other, High dimensional stability under various conditions.

Application : Used in highperformance concrete production.

Micro Silica For RMC

Price 21 INR / Kilograms

Minimum Order Quantity : 10 Tons

Strength : Enhances concrete strength

Chemical Composition : Silicon Dioxide (SiO2) > 85%

Dimensional Stability : Other

Application : ReadyMix Concrete (RMC)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free